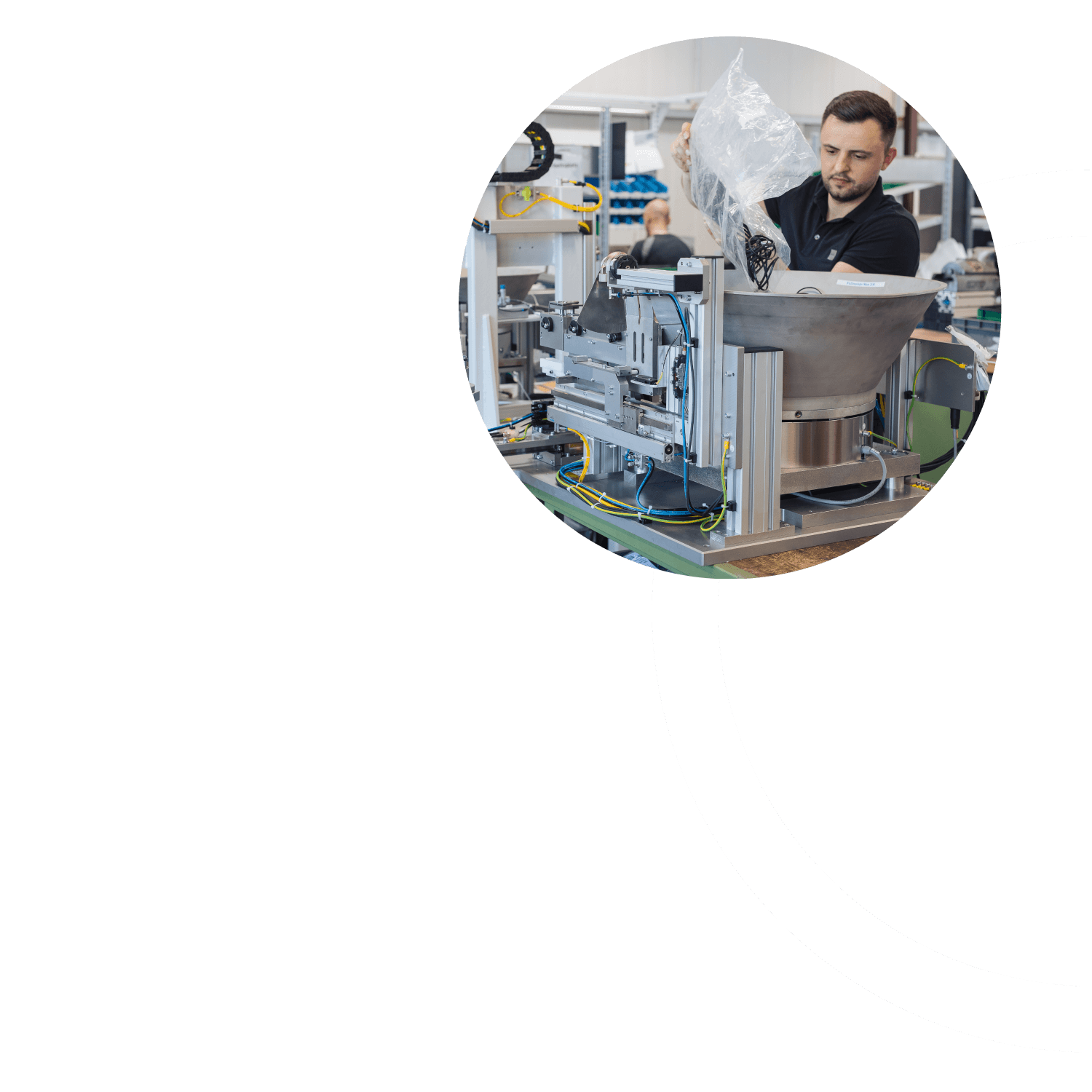

OA/OI stations

THE EXPANSION OF OUR MODULAR SYSTEM FOR MACHINE AND PLANT CONSTRUCTION

For mechanical engineers: The OA / OI stations extend our modular system, which is specially designed for integrators. As a plant builder, designer and planner with general contractor responsibility, you rely on experts for special process technology. If you are looking for solutions that go beyond the specification of the OA3xx series, the OA / OI stations are just right for you.

APPLICATION FIELDS

Standard stations for external as well as internal assembly of seals. For integration into robot cells, rotary table systems and transfer lines.

- For rings from an outer diameter of 35.5 mm

- Dry, oiled and greased ring assembly

- Feeding and assembling O-rings

- Feeding, contour production and assembly (contour seals)

- Feeding, position check and assembly (lip seals)

- Compress, hold and insert (internal assembly of large rings)

- Combine and assemble together (sealing ring / support ring)

- Special applications (diaphragms, hose sections, etc.)

YOUR ADVANTAGES

- Clearly defined mechanical and electrical interfaces

- High availability and reproducibility

- Combination with customer-specific processes

- Solution pool for molded & contoured seals, sealing & back-up rings

- Tested and approved before delivery

- Proven solutions from the market leader

NUMBERS | DATA | FACTS

- Mechanics: All components assembled on a base plate Tested until the ring is transferred to the part

- Electrical: Fieldbus node for PROFINET IO; without control (PLC)

- Pneumatics: Supply connection of the valve terminal (QS-G¼ -8)

- Energy: Compressed air 6 bar (filtered, oil-free and dry) 110-230V AC/50-60Hz,

- Sound emission: sound pressure level < 73dB(A) according to DIN EN ISO 11202

Various optional equipment:

- Lubrication / greasing drum and magazine units

- Assembly and reoiling

- Assembly and leak test

- Assembly with visual control (presence / fit)

- Refill hopper

- Camera monitoring systems and sensor technology

CONTACT / REQUEST

Are you looking for a solution for the assembly of seals? If you can already provide us with the following information, you will help us to advise you in the best possible way:

- Assembly task (internal or external seal)

- Components

- Seal specification (material, cross-section, dimensions)

- Production volume or cycle time

- Desired level of automation (manual, semi-automatic, fully automatic)

We are happy to advise you and look forward to hearing from you!