OA ROTA compact

Small, powerful, innovative

Maximum freedom from twisting thanks to new assembly principle

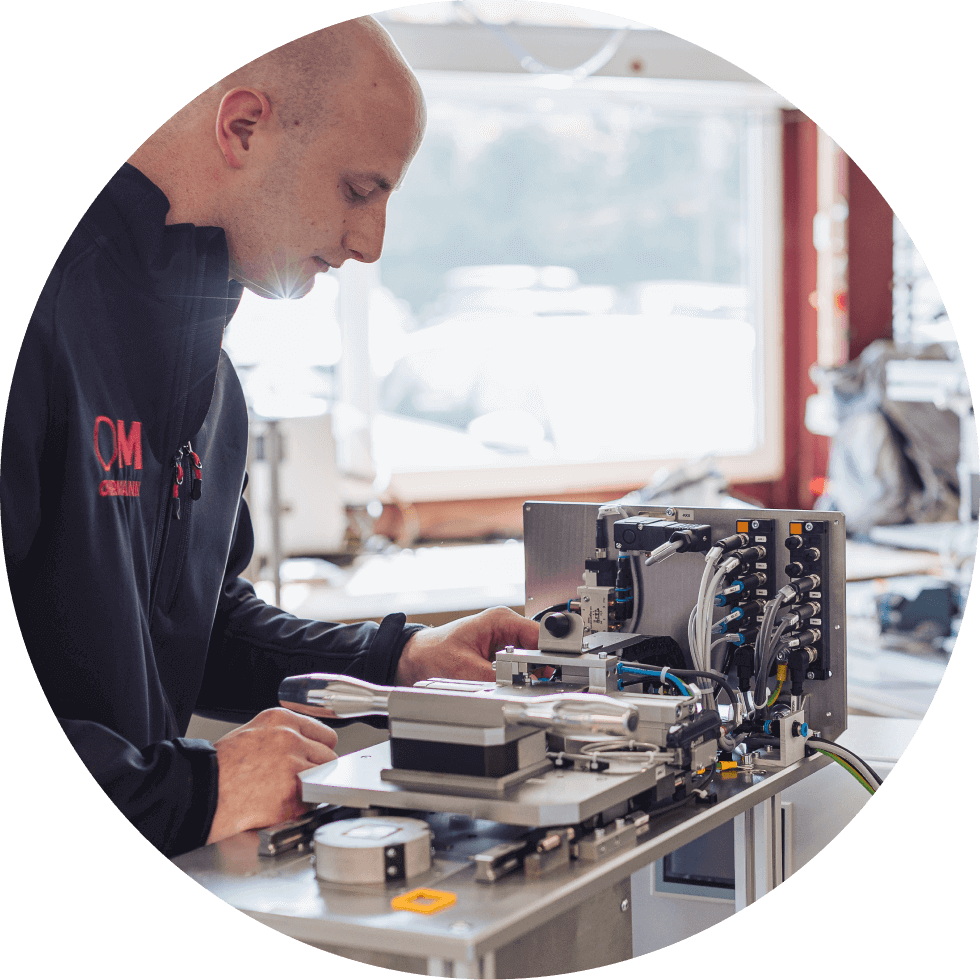

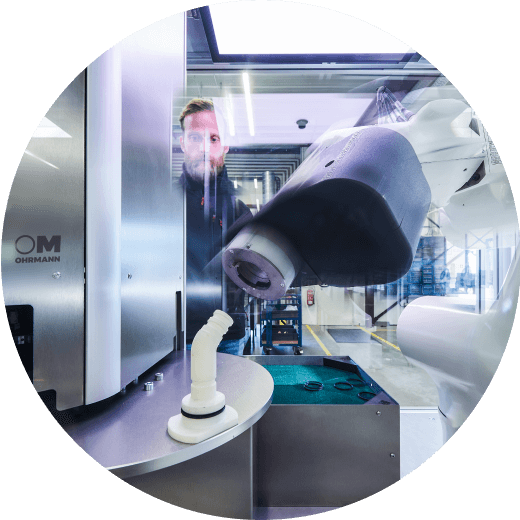

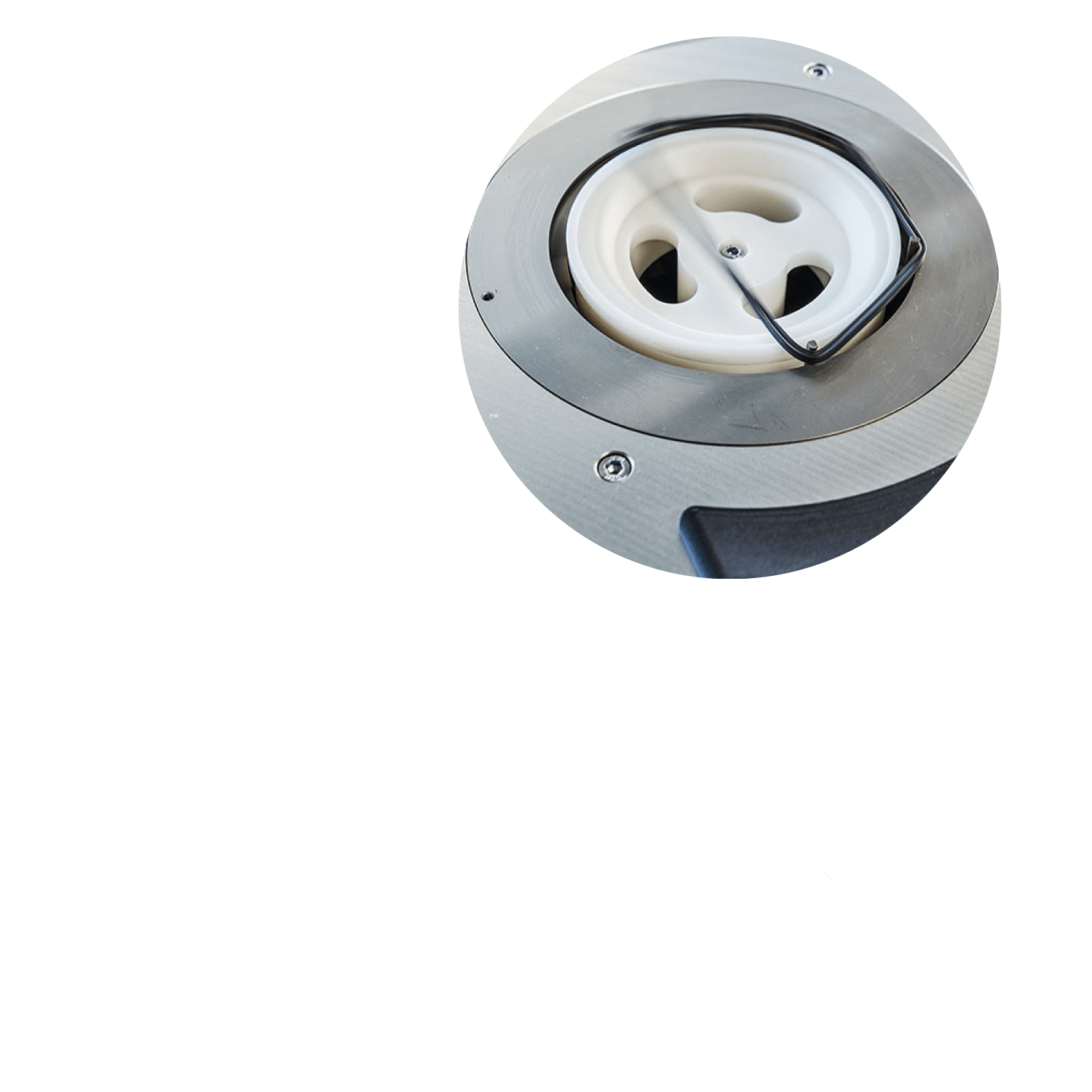

We also have suitable solutions for special requirements. The OA ROTA compact expands and assembles the seal by means of a rotational movement. Only when the seal is almost completely and reliably in the groove does the stripping and retraction of the fingers take place, effectively preventing rolling or flipping. In this way, the new assembly principle guarantees maximum freedom from twisting.

APPLICATION AREAS

- Assembly of external sealing rings

- Perfect for large O-rings and O-rings with small cord thicknesses (e.g. for housings of large electric motors)

- Also ideal for special ring cross-sections (e.g. quad rings, Y-rings, hose seals)

- Large insertion depths possible

YOUR ADVANTAGES

- Maximum freedom from twisting thanks to new assembly principle

- The ring is placed in the groove in an assembly plane. This effectively prevents rolling.

- Simple operation

- Compact design

- Conversion possible

- Assembly also possible with large insertion depths

NUMBERS | DATA | FACTS

- Electrical connection: not required

- Pneumatic connection: 6 bar

- Cycle time including part handling: from 3.0 s (operator-dependent)

- Working range rings: Inner diameter from 10 mm, special designs up to 1000 mm possible

- Weight: from approx. 20 kg

- Dimensions: from 220 x 340 x 250 mm (WxLxH)

CONTACT / REQUEST

If you have a request, please do not hesitate to contact us. We are here to advise you and help you find the best possible solution for your requirements.

By providing the following information, you will help us to support you as quickly as possible:

- Machine comm. no. and type (from the type plate)

- Article number of any required spare/wear parts, if available

- Short description of your requirement

We look forward to hearing from you and will be pleased to help!