Feeding technology - made by Ohrmann

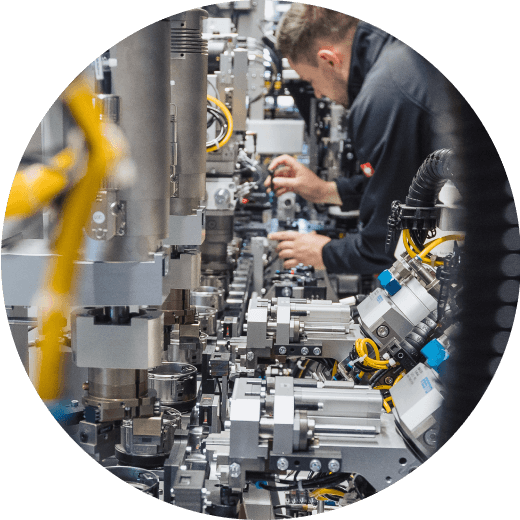

It’s the interaction that counts! We create feeding systems in-house, from vibratory bowl feeders to flexible “bin picking” systems for our machines.

From small semi-automatic machines to complex, fully interlinked assembly systems – the feeding of individual parts is a particular challenge in many cases.

Therefore, our feeders are made by Ohrmann!

A team of experienced specialists designs, manufactures and assembles our feeders and puts them through their paces in our in-house laboratory before integrating them into assembly machines and lines.

We also master specialties

- Dry, oiled and greased seals

- Ring diameter from <1mm to >500mm

- From vibratory bowl feeder to flexible “bin picking” system

- From Anyfeeder to Conveyor tracking

- From <0.1g to >1kg component weight

This in-house expertise is a guarantee for reliable complete systems.

APPLICATION FIELDS

- Ring diameter: from 0.7mm to 250mm

- Weight from <0.1gr to >1 kg

- Cycle time <1s

We find a solution for every seal assembly and feeding task.

YOUR ADVANTAGES

- Many years of internal competence

- Feeding and assembly from a single source

- Feeding tests to ensure feasibility already in the bidding phase

- Test and experimental laboratory for basic principles and specific applications

- Experience with very different systems, custom-fit solution for each component

CONTACT / REQUEST

If you have a request, please do not hesitate to contact us. We are here to advise you and help you find the best possible solution for your requirements.

By providing the following information, you will help us to support you as quickly as possible:

- Machine comm. no. and type (from the type plate)

- Article number of any required spare/wear parts, if available

- Short description of your requirement

We look forward to hearing from you and will be pleased to help!